Services

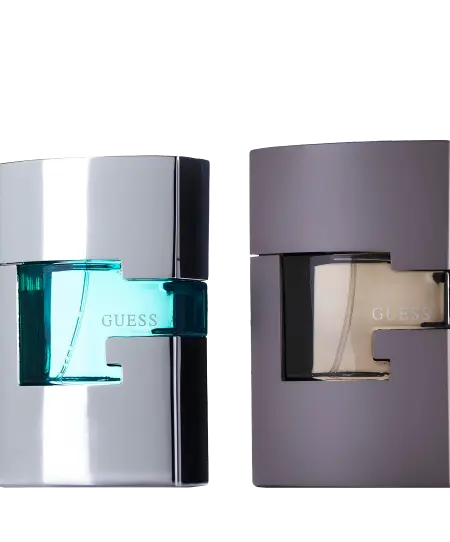

Decotech Inc. has established a reputation for expertise in the decoration of glass bottles and containers for the prestige fragrance, cosmetic, tabletop, spirits and giftware markets across the world.

At Decotech, our mission is to provide our glass packaging customers with the best glass decoration services through cutting-edge glass decoration technology, constant innovation and the highest level of quality and service in the industry. We are constantly researching and investing in new technologies and techniques to offer our clientele.

Glass Decoration Services

Our variety of glass packaging and decorating techniques provides many beautiful options for making your packaging vision a reality. Having applied custom decorations on glass packaging for everything from perfume bottles and candle holders to drinking glasses and liquor bottles, our experienced employees can complete any requested project that comes their way. In order to ensure that your packaging vision becomes a reality, we utilize the latest glass decorating techniques, including the following:

Silkscreen Printing

Spray Coating

Masking

No other glass supplier in the world has every decorating technology under one roof, like Decotech. Because every step of our glass decorating process is completed on-site, at our facility, we consistently deliver our clients shorter lead times and more complex combinations of techniques than any other decorator or glass manufacturer.

While developing your glass packaging decoration, quality is our top priority and our goal is to be the “State of the Art, in the Art of Decorating”. We are dedicated to providing our customers with the highest quality products and services in the glass package decoration industry. Learn how our glass decoration techniques can create a premium brand experience on our Techniques page, and see how we’ve brought our clients’ visions to life on our Samples page.

Turn your vision into reality.

Glass packaging services

Our clients continually challenge us to find innovative solutions for their glass packaging designs and requests.

One-Stop-Shop Glass Sourcing & Management

As an end-to-end solution provider, let us handle the details while you focus on the next big idea. As the only independent decorator in the world to offer complete turnkey glass procurement and decoration services, we can reduce your company’s inventory and take vendor quality management off your mind. As your glass supplier, we manage all production schedules, transportation issues and quality concerns, directly with the glass manufacturer. Our long history of glass purchasing relationships, with all the premiere glass manufacturing companies around the world, gives us the experience needed to manage your glass components professionally.

With our turnkey glass packaging services, our clients enjoy a customized, top-quality product with lower inventory costs, and reduced time-to-market. By working with Decotech, the only thing you will have to file under your inventory is the finished product.

In-house lab testing services

Graphic arts services

Any aspect of your artwork, decoration or design may be developed, modified and produced by Decotech. In our state-of-the-art Product Development and Art Processing Department, we assist our clients in the development of artwork and designs for glass products and packages. We also take any 2D artwork that our clients provide and prepare it for proper 3D application on the production floor. With our on-site graphic arts services, our clients will have peace of mind knowing that their glass bottle or container will be decorated properly and to the highest caliber.

Quality certification & documentation

Protective packaging design & sourcing

There are times when our clients need their decorated glass to leave our facility in a different way than it came in. You may need more delicate partitions or packaging for your specific product. You may need to use formed plastic trays rather than simple cardboard partitions, or you may need anti-static poly-bags to hold your beautifully decorated glass bottles.

Whatever your decorated glass packaging needs are, Decotech has the experience needed to design and source the materials. If we feel that there is a better way to ensure the safe transit of the glass decoration, we will make a recommendation and offer you the option of handling the design and procurement of the packaging materials for your decorated glass.

Working with Decotech Inc.

At Decotech, we aim to be a model of responsible capitalism by providing dignified work, embodying socially and environmentally responsible business practices, committing to continuous improvement and producing things that add beauty to the world.

We have the unmatched ability to coordinate the manufacturing and decoration of our clients’ glassware at the most advanced glass decorating facility of its kind. With our unique glass sourcing and management services, Decotech can shorten your total lead time to a matter of weeks, compared to other suppliers who can take months to deliver a decorated, finished product. Learn more about the benefits of partnering with Decotech for your glass packaging decoration needs.

At Decotech, we aim to be the “State of the Art in the Art of Decorating” for the global prestige fragrance, cosmetic, tabletop, liquor and giftware markets. Decotech has a long history of industry-leading innovation, and today we have access to the most unique and cutting-edge glass packaging decoration techniques and technologies in the industry. Learn more about the innovative glass decoration techniques we can bring to your project.

Decotech is dedicated to excellence, leadership and stewardship in everything we do. As part of this mission, we are committed to protecting the environment around us as well as the health and safety of our employees and members of the communities in which we work and live. Learn more about our commitment to the environment and the recognition we’ve received for reducing our environmental impact.

For close to half a century, Decotech has provided glass packaging decoration services for the finest fragrance, cosmetic, tabletop and giftware houses in the world. At Decotech, we are confident that we can help you make your packaging vision a reality. Get started on your next packaging project by contacting Decotech today. Call us at 201.569.1900 or fill out our online contact form to learn how we can provide solutions for your glass packaging needs.